Efficient Transformer Oil Recovery: Fixing Oil Quality and Sustainability

The Function of Dielectric Transformer Oil in Reliable Power Distribution Equipment

Dielectric transformer oil is a necessary part in the realm of power distribution systems, giving important features that expand beyond plain insulation. Its capability to help with and prevent electric discharges heat dissipation makes certain that transformers operate efficiently and preserve their longevity.

Features of Dielectric Transformer Oil

In addition, dielectric transformer oil plays a vital duty in thermal administration. It efficiently dissipates heat created throughout the operation of transformers, helping with optimal efficiency and extending tools life - dielectric transformer oil. The oil flows within the transformer, taking in heat and transporting it to cooling down radiators or systems, consequently maintaining a secure operational temperature level

Additionally, dielectric transformer oil adds to the avoidance of oxidation and corrosion of inner elements. By giving an obstacle against wetness and air, it maintains the electrical and mechanical properties of the materials used in transformers, minimizing the possibility of premature failure.

Value of Insulation

The integrity of electrical systems heavily depends on effective insulation, which acts as the initial line of defense against electric discharges and short circuits. Insulation materials, such as those made use of in transformers and cords, are essential for keeping the operational integrity of power distribution systems. They stop unexpected existing circulation, shielding both tools and workers from dangerous electric failings.

The value of insulation prolongs past plain protection; it additionally makes sure the durability of electrical components. Top notch insulation materials can hold up against environmental stress factors, such as moisture, temperature variants, and mechanical impacts, therefore decreasing the chance of insulation break down. This strength is critical in maintaining the performance of power circulation framework.

Warmth Dissipation Device

When thinking about the performance of power circulation systems, understanding the heat dissipation mechanism is vital, as too much heat can cause devices failure and reduced operational life-span. Dielectric transformer oil plays a crucial duty in this process by facilitating effective heat move away from essential components within the transformer.

The primary mechanism of warm dissipation in transformers includes convection, conduction, and radiation. Dielectric oil carries out heat far from the windings and core, permitting for a more uniform temperature level circulation. The oil flows within the transformer, either naturally or through required blood circulation, improving convective warmth transfer. This flow is essential, as it makes certain that warm generated by electric losses is effectively carried to the cooler locations of the transformer.

The high thermal conductivity of transformer oil makes it possible for rapid heat exchange, guaranteeing that temperature level rises are reduced. Recognizing these mechanisms is vital for the ideal style and operation of transformers within the power circulation network.

Impact on Transformer Long Life

Effective warm dissipation straight affects transformer durability, as original site extended exposure to elevated temperature levels can accelerate insulation degradation and product tiredness. Dielectric transformer oil plays an important role in this procedure by successfully moving warmth far from the core and windings, preserving optimum operating temperatures. The thermal conductivity and certain warm capability of transformer oil are necessary qualities that boost its ability to take in and dissipate warmth generated throughout transformer operation.

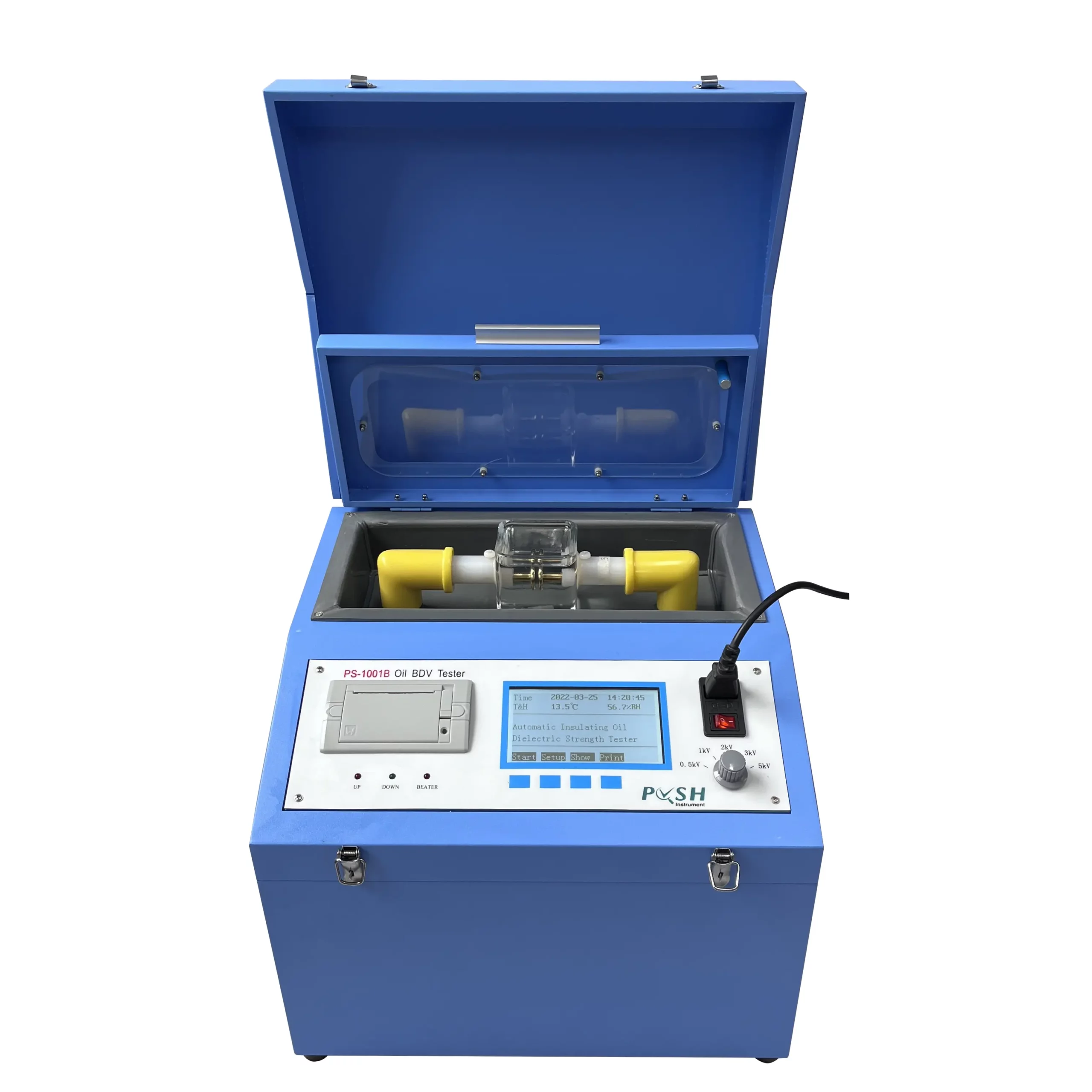

Additionally, the oil's dielectric residential or commercial properties are crucial for protecting against electric failure and making certain insulation honesty. A high-grade dielectric oil reduces the danger of arcing and dielectric failure, which can lead to catastrophic transformer failures and significantly shorten life span. Normal surveillance of the oil's problem is vital to recognize pollutants and deterioration products that might endanger its performance.

Furthermore, the chemical stability of the dielectric oil is extremely important; oils that stand up to oxidation and thermal deterioration add to long term insulation life and general transformer dependability. By reducing the effects of warmth and electrical tension, dielectric transformer oil functions as a critical element in improving the durability and performance of power circulation transformers, thus guaranteeing a more reliable power supply.

Ecological Factors To Consider

Environmental considerations bordering dielectric transformer oil are significantly crucial in the context of sustainable power circulation systems. The use of traditional mineral oil offers difficulties due to its potential ecological dangers, including toxicity to aquatic life, dirt contamination, and problem in biodegradation.

Furthermore, the disposal and recycling of dielectric oil are critical parts of environmental stewardship. Proper monitoring methods must be applied to avoid spills and leaks, which can have destructive impacts on neighborhood communities. Regulatory frameworks are evolving to implement strict guidelines regarding the handling, storage, and disposal of transformer oils, guaranteeing that utilities prioritize environmental honesty.

Furthermore, the life process assessment of dielectric transformer oils is coming to be a vital facet of examining their total environmental effect. This assessment includes oil manufacturing, usage, and end-of-life disposal. By taking on sustainable methods and deciding for eco-friendly alternatives, power circulation systems can dramatically minimize their environmental impact while maintaining operational integrity.

Verdict

Finally, dielectric transformer oil is necessary for the integrity and efficiency of power circulation systems. Its features as an insulating medium and a heat dissipator substantially add to the avoidance of electrical discharges and the maintenance of optimal operating temperatures. Moreover, informative post the oil's capacity to decrease oxidation and deterioration enhances transformer long life, therefore reducing maintenance costs. On the whole, high-quality dielectric oil plays a crucial duty in making certain the honesty and efficiency of electrical systems.

Dielectric transformer oil is an essential part in the world of power distribution systems, supplying crucial functions that expand past mere insulation.Dielectric transformer oil serves numerous important functions in power distribution systems, making certain both operational efficiency and safety and security. Dielectric transformer oil plays a vital function in this process by efficiently moving warm away from the core and windings, maintaining optimal operating temperatures. The thermal conductivity and specific warm ability of transformer oil are important characteristics that boost its capability to my website dissipate and take in heat created during transformer procedure.

A top notch dielectric oil decreases the threat of arcing and dielectric failing, which can lead to disastrous transformer failings and substantially shorten service life. electrical insulating oil.